It can be very difficult to understand the various label terms in the business world.

What is a high-tack label?

What is a label liner?

What is a core and an OD?

What does tear strength mean?

This blog post will help you to understand all of these terms and more.

The Quick Guide to Label Terms

There are hundreds of label terms that we could have included in this guide. For the sake of keeping things short and sweet, we will only include the most important ones.

Remember these terms when you are looking to order any type of direct thermal or thermal transfer label. They will help you to get the best label for your application.

Abrasion Resistance: The degree to which a label surface, including printing and protective coatings, is able to resist rubbing or wearing from friction. Also referred to as “rub” or “scuff” resistance.

Acrylic: A general chemical term of a particular family of thermoplastic resins based on acrylic acid and its derivatives.

Acrylic Adhesive: A pressure-sensitive adhesive based on high-strength acrylic polymers. It can be coated as a solvent or emulsion system.

Adhesion: The state in which two surfaces are held together by interfacial forces. Measure of the strength with which one material sticks to another.

Adhesive: A substance capable of holding materials together by surface attachment.

Adhesive Build-Up: The undesirable transfer of adhesive from label material to machinery parts during conversion or application.

Asset Tag Labels: Labels or tags used to speed the regular inventory of capital assets and provide a timed log of that inventory. These are manufactured to a variety of specifications defined by the product owner. Bar code type, background color, sequencing, laminating, and die cutting are all options. Here is Zebra’s guide to Asset Management.

Backing: The carrier sheet of material, as opposed to the face material, in a pressure sensitive lamination. It always has a release coating applied so that the adhesive will not stick permanently to the backing. Also known as the release liner.

Bar Code: In optical reading, a system of symbols which identifies data through length, position size or thickness of lines or symbols. Codes are normally machine printed.

Bar Code Reader: A device used to identify and read bar code symbols.

A Motorola Bar Code Reader

Bleed: When the printed image extends beyond the trim edge of the label.

Brightness: The reflectivity of a sheet of paper for blue light measured under standardized conditions on a particular instrument designed and calibrated specifically for the purpose. Strictly speaking, brightness is not a colormetric quantity.

CAD: Computer Assisted Design.

Chemical Resistance: The resistance of a pressure sensitive label to the deteriorating effects resulting from exposure to chemicals under specified conditions.

Clinical Laboratory Labels: Labels that are used to insure identity and integrity of vialed laboratory specimens through a variety of means. The labels can be used to identify date, collector, shipping container seal, and specimen ID, and may also provide double duty as a sealing document for the specimen. The labels can also be die cut in a sophisticated manner or be made from specialty face stocks which provide evidence of tampering. This Zebra page will provide more information on Laboratory label applications.

Coating: The emulsion, varnish, or lacquer applied to a label, often over a printed surface, to give it added protection from moisture or abrasion, or to give the finished surface receptivity to subsequent printing.

Cohesion: The internal strength of an adhesive mass; resistance to flow, and resistance to failure in the adhesive when labels are removed or are under stress. See cohesive strength. Also referred to as cohesive strength, internal bond, and shear.

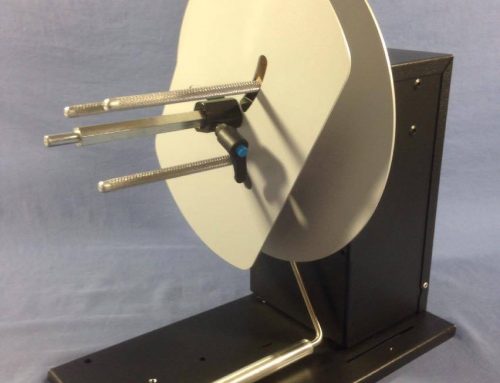

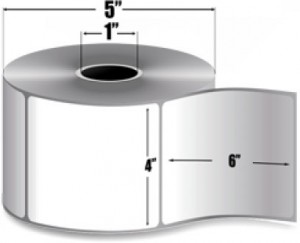

Core: A paper, plastic or metal tube on which paper, film, or foil labels are wound for shipment. A Zebra desktop label printer will use media with a 1″ core.

Example of labels with a 1″ core

Die: Hardened steel or tungsten carbide tools or devices used for imparting or cutting a desired shape, form, or finish to or from a material. A device used in converting machinery for cutting only the face material of a pressure sensitive laminate or for punching out shapes from the entire laminate or any other label material.

Die Cut Label: Pressure sensitive labels die-cut to the release liner from which the matrix has been die cut and usually removed.

Direct Thermal Labels: Labels used with a printing method utilizing heat impinged upon a specially coated substrate so that the heat turns the surface black. No ribbon is required.

DPI: Dots per inch. Resolution is expressed as the number of lines or halftone dots per inch, also called screen ruling. This is also used to express the print resolution of digital printing machines including laser printers, thermal printers and ink jet printers.

Face Material: Any paper, film, fabric, laminate or foil material suitable for converting into pressure sensitive label stock. In the finished construction this web is bonded to the adhesive layer and becomes the functional part of the construction.

Fading: A gradual decrease in brilliance of color. The term is often applied to the change in color produced by exposure to light.

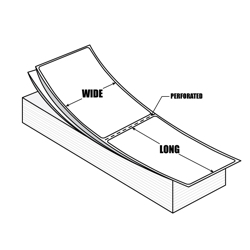

Fan Fold: Labels manufactured from a continuous web of label stock and then folded into a zigzag accordion style format for packing flat in packaging. The fold is created by horizontal perforations in the release liner. Fan folded labels are mostly used for data processing applications.

An example of a stack of Fan Fold Labels

Flood Coat: The coating of an entire label surface with ink, adhesive or varnish.

Four-Color Process: Printing with cyan, yellow, magenta, and black (CYMK) inks using screens to reproduce the wide spectrum of colors. This is referred to as process printing or CMYK printing.

ISO: The International Organization of Standards (ISO) is a non-governmental organization which occupies a special position between the public and private sectors, developing worldwide technical standards and providing a consensus on solutions that meet both the requirements of the business and the broader needs of society. The ISO issues the ISO 9001:2008 quality standard, as well as more than 14,000 international standards for business and government.

Label: The functional portion of a pressure sensitive construction comprising the face material and adhesive, die cut into various shapes.

Lamination: A plastic film bonded by heat, adhesive and/or pressure to a printed web for protection or appearance. Two or more materials bonded together functioning as one.

Liner: The carrier sheet, as opposed to the face, of material in a pressure sensitive lamination. It usually has a release coating applied so the adhesive will adequately stick to the backing.

M: Abbreviation for a quantity of 1,000.

Matte Finish: Paper coatings, inks, varnishes, and laminates may all be obtained with a matte finish, which diffuse the reflection of light to provide a flat, non-glossy finish.

Mil: A unit of thickness measurement used for label materials. 1 mil=0.001 inch=100 gauge.

OD: The outside diameter (OD) of a cylinder, roller or roll of labels. The OD of a finished roll of labels is often specified, especially when labels will be mounted on a printing or application machine with certain OD size limitations. Zebra Desktop Printers require media with an OD of 5 inches.

Opaque: A material or surface that is not transparent, translucent or transmits light. Opaque label materials are often used when covering up existing text on a product. The opacity of the label assures the ink underneath the label will not be visible.

Overrun: Production manufactured in excess of the specified order quantity. The industry standard is +/-10%.

Pantone Matching System: An international system of matching color for printing, designating unique colors by standard Pantone Matching System® (PMS) numbers. Pantone is known worldwide as the standard language for color communication from designer to manufacturer to retailer to customer. See our Pantone color chart for reference.

Perforation: A line or row of cuts or tiny holes that enable a label or its liner to be folded, torn off or separated easily. Perforation may be horizontal or vertical, with standard or microperforations. Perforations can also allow labels to be segmented as needed by an application. A very important addition to the Guide to Label Terms.

Permanent Adhesive: An adhesive with relatively high ultimate adhesion to a wide variety of surfaces.

Pharmaceutical Label: There are a wide range of applications and solutions required for pharmaceutical labels. Some applications may require the inks to be autoclaved or sterilized, while others may need to be stored in a freezer. The label will often need secondary information printed with a thermal transfer printer.

Piggyback Labels: Pressure-sensitive label constructions that have two release coated liners, two layers of adhesive and a face material which enables the label to be applied, complete with the backing, for further or future application.

Plate: The image carrier in letterpress and flexographic printing. Flexographic printing plates are made of a flexible polymer and wrap around a print cylinder for printing. Each color used on a label requires its own printing plate and ink station.

Polyester: Made of polyetherylene terephthalate (PET), it is a high-performing film with excellent resistance to moisture, solvents, and oils. It provides excellent strength, clarity, and dimensional stability.

Polypropylene: Similar to polyethylene but stronger and having a higher temperature resistance. Various thermoplastics are polymers of propylene with excellent clarity. It is also used in various thicknesses in the printing of labels as well as backing or liner materials.

PVC: Vinyl; polyvinyl chloride.

Residue: The adhesive left on substrate when a label is removed.

Smudge Resistance: Resistance of a printed paper surface to ink blurring or smearing and thus related to the absorption of the paper.

Solvent Resistance: The resistance of a pressure sensitive label to the action of specific organic liquids. May apply to either adhesive or printing.

Stock: Paper or other material to be converted.

Synthetics: Those materials developed and manufactured through chemistry, which tend to replace natural materials.

Tack: The property of a pressure sensitive label which causes it to adhere to a surface instantly with a minimum of pressure and contact time. It is the feeling of stickiness obtained when the surface of an adhesive is touched or when a label is applied to a surface and quickly pulled away.

Tag Label: Labels on heavy paper or tag stock with die cut holes so labels can be folded over a packaging material as in a header or hanger label.

Tags: Any identification that is only partially affixed to the product or item. System tags are converted through roll-fed production equipment. Merchandise tags are converted through narrow web roll-fed production equipment.

Tamper-Evident Label: A pressure sensitive construction made of materials which will partially destruct, indicating that a package, label or container has been tampered with.

Tear Strength: Force required to tear a specimen under standardized conditions. This is measured with an instrument that simulates use conditions under which tearing might be accomplished.

Thermal Transfer: Similar to a thermal print system, except a one-time ribbon and smooth surfaced materials are used to eliminate the problems of fading or changing color inherent in the direct thermal print process.

Thickness: Distance from one surface of tape, label or adhesive to the other, usually expressed in mils, or thousandths of an inch. This is normally measured under slight pressure with a special gauge.

Translucent Label: Material capable of transmitting light, yet not totally transparent.

2D Bar Codes: Unlike conventional bar codes, these two-dimensional bar codes are able to carry information in both horizontal and vertical planes, enabling more information to be printed in a smaller amount of space.

An example of a 2D Bar Code

Tyvek: Du Pont’s registered trademark for its non-woven, spun-bonded polyolefin material that brings together several of the best properties of paper, textile fibers and film into one synthetic material. It is extremely strong and resistant to continuous folding, tearing, and weather conditions.

UPC: The Universal Product Code (UPC) is a 12-digit code used by manufacturers to identify themselves and their products. The allocation of the manufacturers identification number and the administration of the code system is done on the payment of an annual fee by manufacturer to the Uniform Code Council. The allocated code enables manufacturer members of the Council to identify trade items, logistics units, assets, locations, and service relations to bring efficiency into their supply chains.

Variable Data Printing: Warehousing, distribution, shipping, storage and tracking of all use labels that are printed with variable data. This variable information printing may be in the form of variable text, bar codes, sequential numbers, batch or date codes. They are usually printed with thermal transfer printers which ensure absolute legibility or with impact printing systems, such as dot matrix printers.

Varnish: A clear protective coating either glossy or matte in finish that contains no coloring pigments or dyes. When printed or coated over the top of a substrate, the varnish provides a protective finish that enhances appearance and increases durability.

Wrap-Around Label: Label that extends completely around bottle or can and overlaps itself.

And there you have it.

These are the most useful terms to know when it comes to labeling applications.

This guide to label terms will help you decipher the world of “label lingo”. Keep it handy anytime you are confused about anything related to printers or printer media.

At PLS, we know our labels. Feel free to contact us anytime at 1-844-458-1078, or email us at info@professionallabelsolutions.com. Our sales reps are happy to address any questions or concerns that you might have. We’ll help make sure we provide you with efficient service, proper and useful information, and most important of all: value.